Automotive industry and suppliers

Industrial electronics for tomorrow's mobility

Industrial electronics plays an indispensable role in automotive production and its suppliers. From the design and manufacture of vehicle components to the automation of entire production processes, modern electronic systems ensure that the automotive industry becomes more efficient, precise, and sustainable. Through the use of innovative controls, automation technology, and measurement technology, industrial electronics contributes to increasing quality, reducing production costs, and simultaneously reducing the automotive industry's ecological footprint.

Smart production: AI makes factories smart

Artificial intelligence is revolutionizing automotive production: Smart factories use AI-supported systems for real-time monitoring, predictive maintenance, and process optimization. Machine learning analyzes sensor data, detects anomalies early, and prevents unplanned downtime. Digital twins simulate manufacturing processes to maximize efficiency and quality.

The intelligent networking of machines, robots, and supply chains creates flexible production systems that adapt dynamically to market requirements. This makes manufacturing not only more efficient, but also more sustainable and cost-effective

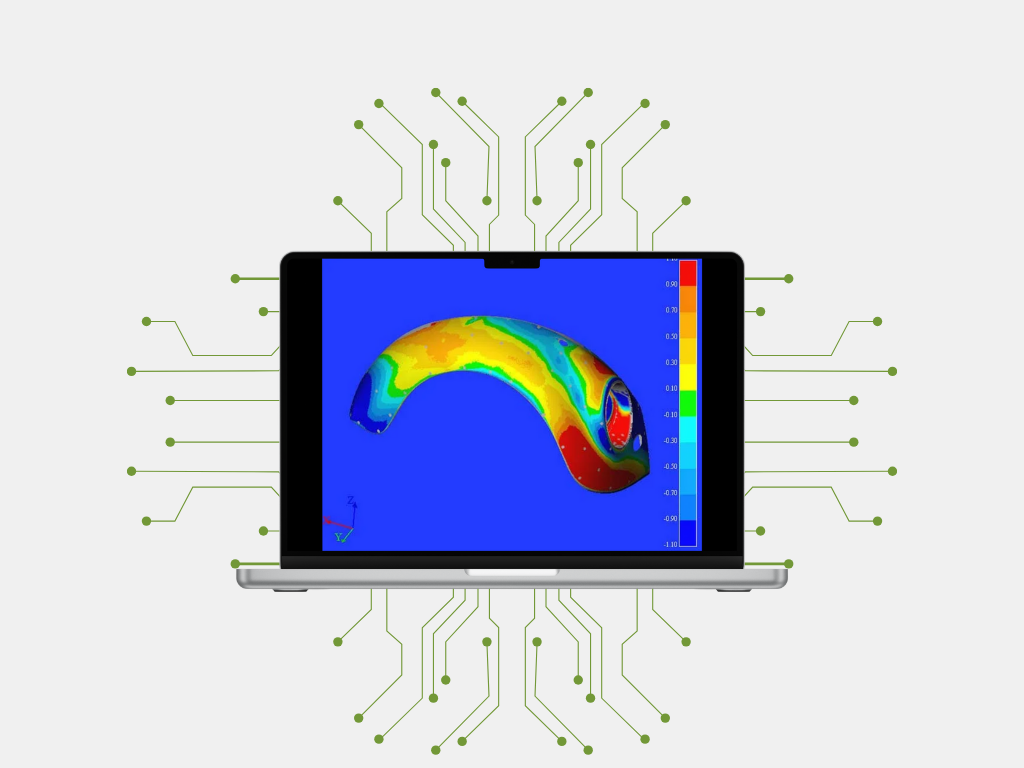

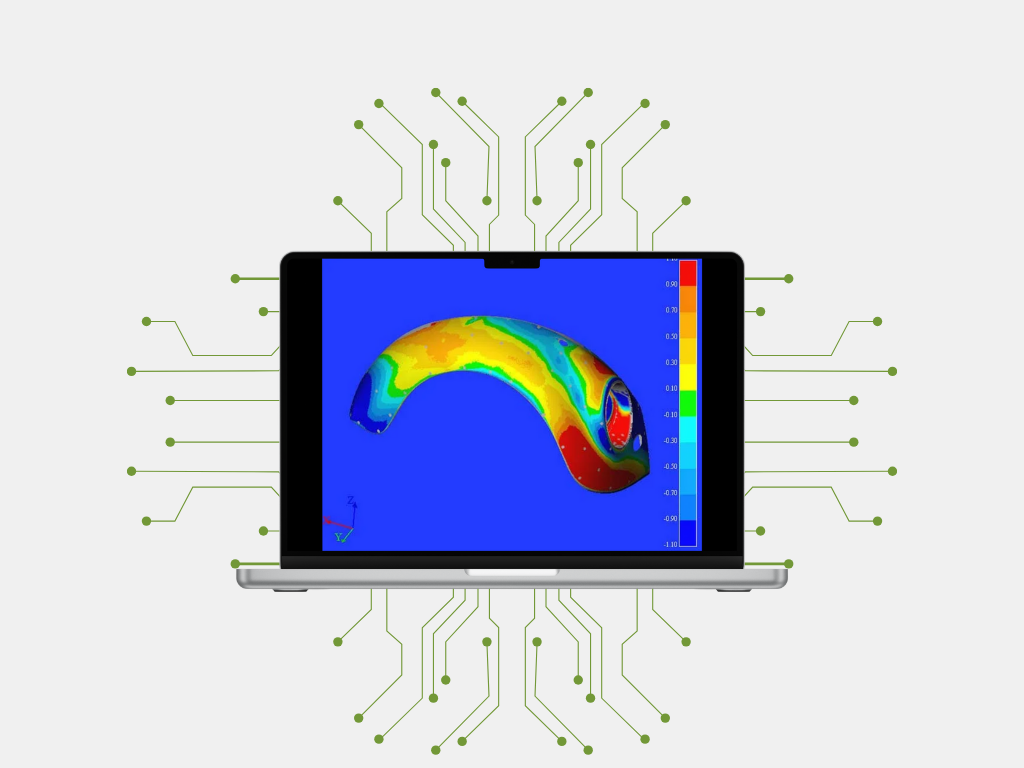

Measurement technology – precision in quality control

In the automotive industry, where precision and quality are paramount, metrology systems are essential to ensure that all vehicle components meet safety and functional requirements. With the support of advanced industrial electronics, automakers and suppliers can maximize the efficiency of their production processes while ensuring the quality and safety of their products.

Smart production: AI makes factories smart

Artificial intelligence is revolutionizing automotive production: Smart factories use AI-supported systems for real-time monitoring, predictive maintenance, and process optimization. Machine learning analyzes sensor data, detects anomalies early, and prevents unplanned downtime. Digital twins simulate manufacturing processes to maximize efficiency and quality.

The intelligent networking of machines, robots, and supply chains creates flexible production systems that adapt dynamically to market requirements. This makes manufacturing not only more efficient, but also more sustainable and cost-effective

Measurement technology – precision in quality control

In the automotive industry, where precision and quality are paramount, metrology systems are essential to ensure that all vehicle components meet safety and functional requirements. With the support of advanced industrial electronics, automakers and suppliers can maximize the efficiency of their production processes while ensuring the quality and safety of their products.

Full power for e-mobility – with reliable industrial electronics

Electromobility

Electromobility is driving transformation in the automotive industry. Increasingly powerful battery technologies, more efficient drive systems, and a growing charging network are making electric vehicles more suitable for everyday use. Manufacturers are investing in innovative production methods to optimize range and charging times.

At the same time, production is changing: lightweight construction, smart energy management systems, and sustainable materials are coming into focus. Electromobility is setting new standards for efficiency and environmental friendliness – and accelerating the path to climate-neutral mobility.

Strong partners: Automotive suppliers as drivers of innovation

Automotive supplier

Nothing works without automotive suppliers – they deliver high-tech components that make modern vehicles smarter, safer, and more sustainable. Whether it's high-performance battery cells, connected assistance systems, or innovative lightweight materials – suppliers are crucial for progress and efficiency.

The industry is facing challenges: Increasing demands for sustainability, digitalization, and new drive technologies require flexible production processes. Those who position themselves innovatively will remain a key player in the mobility of the future. We supply spare parts from leading manufacturers such as Siemens, B&R, Beckhoff, SEW Eurodrive, Danfoss, and Endress+Hauser and offer professional repair services.