Food industry

High-tech for high quality: Industrial electronics in food production

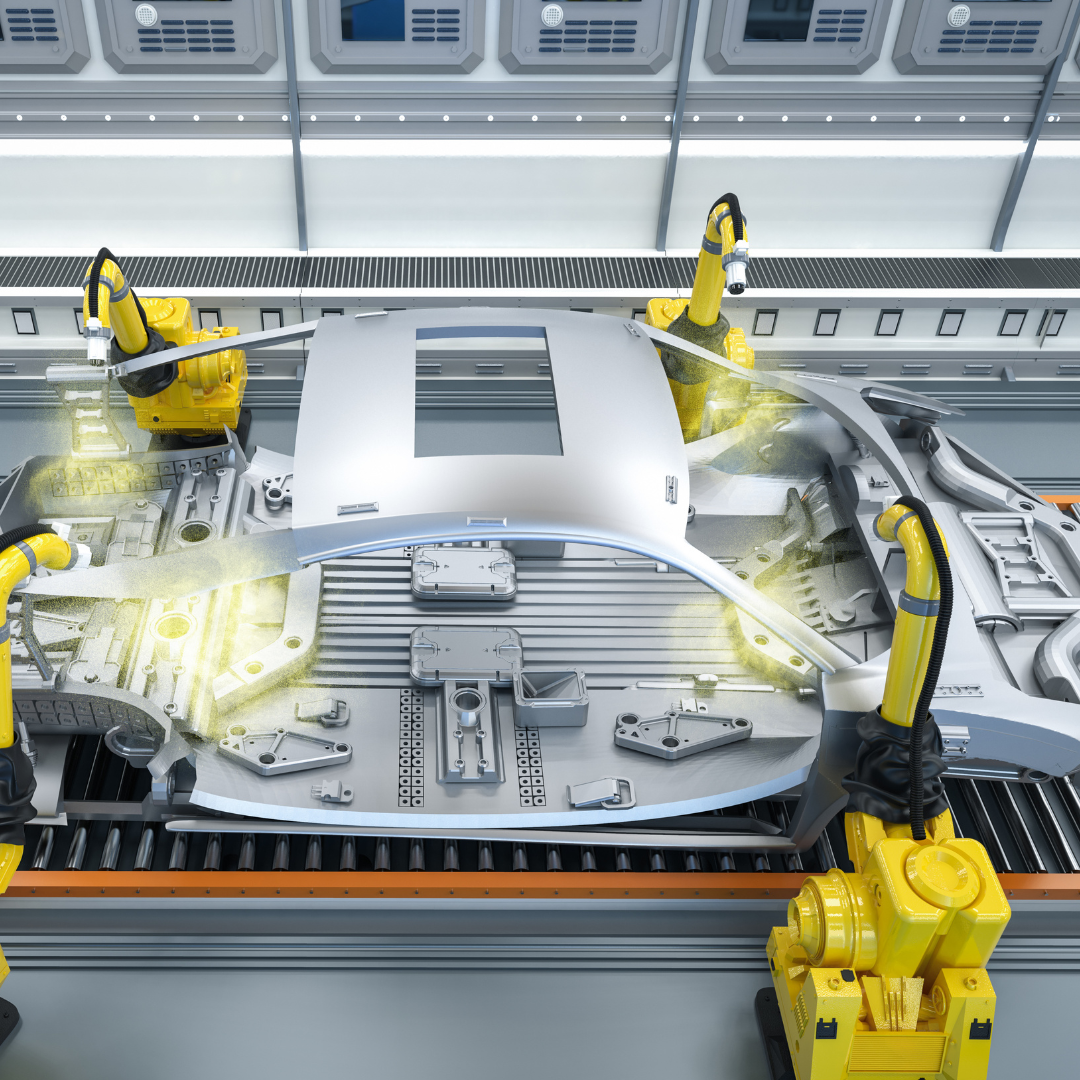

The food industry is facing new challenges: rising demand, strict hygiene regulations, and the desire for greater sustainability require innovative solutions. Modern industrial electronics plays a key role in this by automating production processes, increasing efficiency, and ensuring the highest quality standards.

Automated systems ensure precise processing, filling, and packaging, while smart sensors monitor temperature, humidity, and hygiene in real time. AI-supported systems optimize production processes, reduce waste, and guarantee consistent quality. Robots handle delicate tasks such as sorting and portioning food, while innovative measurement technology detects contaminants and ensures the highest safety standards.

Waste less, gain more: Efficiency through AI

Food waste and high production costs are key challenges facing the industry. AI-supported systems optimize processes, analyze production data in real time, and minimize waste. Intelligent controls enable raw materials to be processed more precisely, fill quantities to be calculated accurately, and packaging materials to be used efficiently.

Leading manufacturers like Siemens rely on AI-based automation with the Simatic S7 controller series to flexibly adapt production processes and optimally utilize resources. Machine learning recognizes patterns in production and automatically adjusts parameters to reduce energy consumption and material usage. This makes food production not only more sustainable but also more economically efficient.

Clean thing: Hygiene through smart sensors

Hygiene is a top priority in food production. Modern sensors from manufacturers such as Sick, Endress+Hauser, and IFM monitor temperature, humidity, and contamination risks in real time to ensure the highest safety standards. Optical sensors detect contamination, conductivity sensors measure cleaning agent residues, and infrared sensors check surface temperatures without contact. Automated cleaning systems and contactless controls minimize the risk of germ transmission. Smart measurement technology detects deviations early and ensures consistent product quality – a crucial step toward greater safety and efficiency.

Waste less, gain more: Efficiency through AI

Food waste and high production costs are key challenges facing the industry. AI-supported systems optimize processes, analyze production data in real time, and minimize waste. Intelligent controls enable raw materials to be processed more precisely, fill quantities to be calculated accurately, and packaging materials to be used efficiently.

Leading manufacturers like Siemens rely on AI-based automation with the Simatic S7 controller series to flexibly adapt production processes and optimally utilize resources. Machine learning recognizes patterns in production and automatically adjusts parameters to reduce energy consumption and material usage. This makes food production not only more sustainable but also more economically efficient.

Clean thing: Hygiene through smart sensors

Hygiene is a top priority in food production. Modern sensors from manufacturers such as Sick, Endress+Hauser, and IFM monitor temperature, humidity, and contamination risks in real time to ensure the highest safety standards. Optical sensors detect contamination, conductivity sensors measure cleaning agent residues, and infrared sensors check surface temperatures without contact. Automated cleaning systems and contactless controls minimize the risk of germ transmission. Smart measurement technology detects deviations early and ensures consistent product quality – a crucial step toward greater safety and efficiency.

Refreshingly efficient: industrial electronics in beverage production

Beverage industry

The beverage industry is facing increasing demands for efficiency, quality, and sustainability. Modern industrial electronics ensure that filling and packaging processes are faster, more precise, and more resource-efficient. Automated systems control production in real time, while smart sensors monitor fill levels, pressure, and temperature.

Leading manufacturers like Siemens rely on intelligent automation with the Simatic S7 controller series and Sinamics drive systems to minimize waste and reduce energy consumption. High-precision flow sensors from Endress+Hauser and VEGA ensure precise dosing and reduce waste. This is how the beverage industry combines state-of-the-art technology with sustainable production – for the highest quality in every sip.

Protection and freshness

Food and packaging industry

In food production, packaging is crucial for shelf life, hygiene, and sustainability. Modern industrial electronics ensure that packaging processes are precise, efficient, and resource-saving. Smart sensors monitor fill levels, sealing, and material usage, while AI-supported controls flexibly adapt production lines.

Leading manufacturers like Siemens rely on maximum efficiency and precision with their S7-1200 controller series and Masterdrive drive systems. Automated packaging solutions with robotics and intelligent conveyor systems reduce material waste and optimize the entire process. The connection between the food and packaging industries is becoming increasingly smarter – for safe, sustainable, and economical packaging solutions.